Protective coating

Understanding Protective Coatings

Essential FAQs for Industrial and Commercial Applications

FAQs

Protective coating in industrial and commercial settings involves applying specialized treatments to surfaces to guard against corrosion, chemical damage, and environmental wear. It is essential for maintaining the structural integrity and functionality of facilities and equipment.

In industrial and commercial environments, protective coatings are vital for protecting assets from extreme conditions, including high temperatures, chemical exposures, and mechanical wear. This protection significantly extends the lifespan of assets and reduces maintenance and replacement costs.

Protective coatings can be applied to a wide range of surfaces, including steel structures, warehouse floors, manufacturing equipment, and exterior walls of commercial buildings. Each application is tailored to withstand specific environmental factors and usage demands.

The longevity of protective coatings in commercial and industrial settings can vary based on the coating type and the operational environment. Generally, these coatings are designed to last between 5 to 15 years, depending on the level of exposure to harsh conditions.

The application process involves thorough surface preparation, which may include abrasive blasting and chemical treatments, followed by the application of the coating. Professional application ensures uniform coverage and maximum durability to withstand harsh industrial and commercial environments.

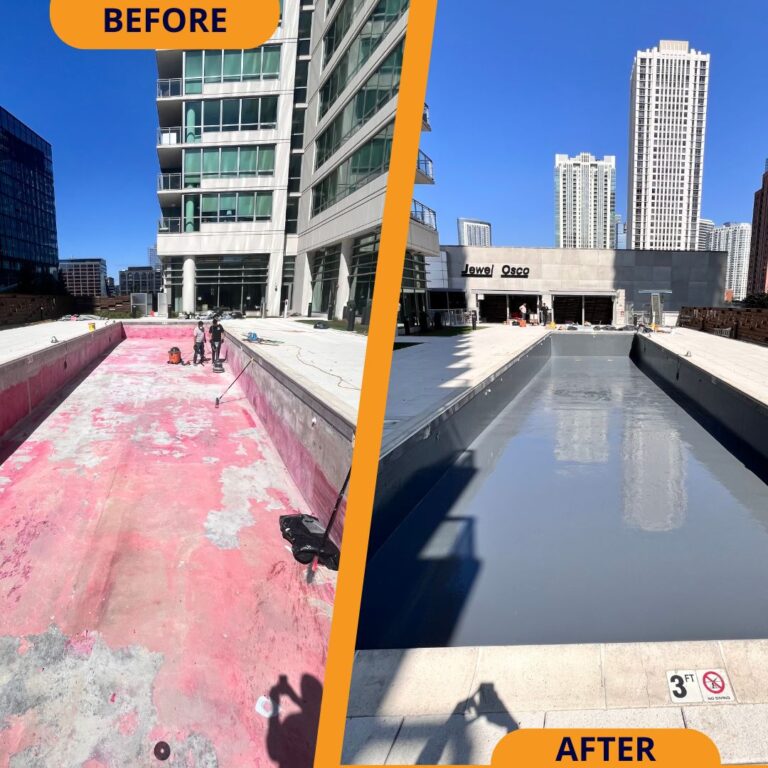

Past Projects

P.C for Concrete

- Prevent concrete degradation with advanced coatings that shield against chemical exposure, weather effects, and thermal cycles, reducing cracks and surface wear.

- Extend your facility’s infrastructure lifespan with durable protective coatings that minimize repair needs by effectively preventing cracks and structural wear.

- Enhance your property’s aesthetic with high-quality concrete coatings that offer vibrant, long-lasting color and finish while hiding and preventing cracks.

- Cut long-term maintenance costs with protective concrete coatings that offer extended service life, crack prevention, and minimal upkeep requirements.

- Implement epoxy sealers to block moisture infiltration in concrete, safeguarding against water damage, mold growth, and crack exacerbation in facilities.

P.C for Metal

- Prevent metal corrosion with specialized coatings that protect against harsh environmental conditions, chemical attacks, and salt exposure, extending lifespan.

- Apply high-temperature resistant coatings to protect metal surfaces from extreme heat and thermal shock, preventing weakening and structural damage.

- Reduce maintenance and replacement costs with durable metal coatings that extend the service life of your equipment and infrastructure.

- Boost metal structural integrity with coatings that resist rust, chemical wear, and environmental degradation, ensuring long-term durability and safety.

Our services

Corrosion Control

Chemical Protection